- SCOPE/USE:

The Code IS 4031-Part 4 covers the procedure for determining the quantity of water required to produce a cement paste of standard consistency.

- DEFINITION of CONSISTENCY of Cement:

The standard consistency of a cement paste is defined as that consistency which will permit the Vicat plunger G (dia. 10 ± 0.05 mm) to penetrate to a point 5 to 7 mm from the bottom of the Vicat mould when the cement paste is tested using Vicat apparatus.

- SAMPLING:

The samples of the cement shall be taken in accordance with the requirements of IS: 3535- 1986* and the relevant standard specification for the type of cement being tested. The representative sample of the cement selected as above shall be thoroughly mixed before testing.

- TEMPERATURE AND HUMIDITY:

The temperature of moulding room, dry materials and water shall be maintained at 27 ± 2°C. The relative humidity of the laboratory shall be 65 ± 5 percent.

- MATERIALS REQUIRED: Cement and Water.

- APPARATUS: –

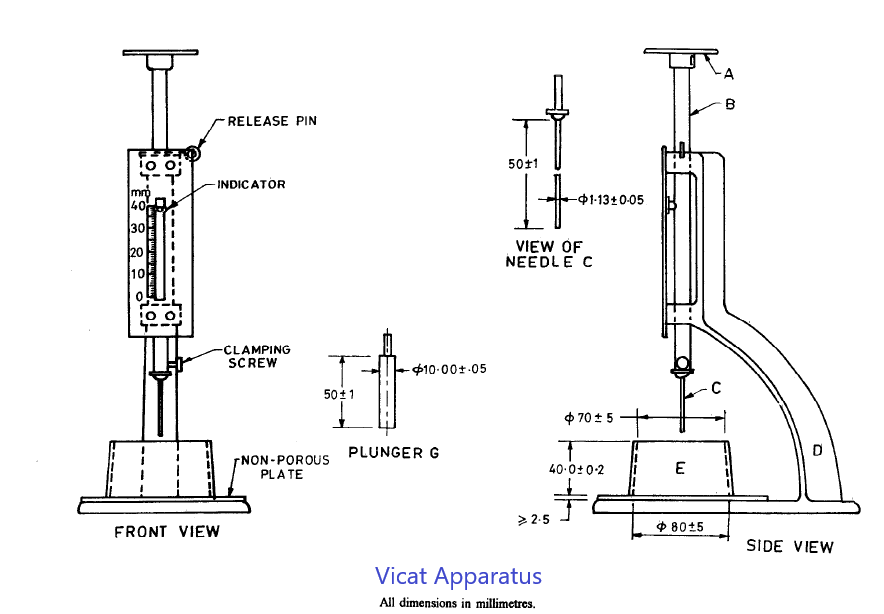

- Vicat apparatus

- Diameter of larger end of plunger: 10 ± 0.05 mm as per IS 5513.

- Weight balance (Permissible variation at a load of 1000 g shall be ± 1.0 g)

- Non-porous plate (One glass plate 300 x 450mm).

- Glass measuring cylinder, 200 or 250ml

- Gauging Trowel

- Standard Weights

- Vicat Apparatus:

- Gauging Trowel– The gauging trowel shall be made of mild steel and shall be in accordance with Fig below. The trowel blade shall be of minimum thickness 1.5 mm and of length 195 mm and shall be provided with a wooden handle. The trowel shall weigh 210 ± 10 g. As per IS 10086-1982.

Gauging Trowel

Gauging Trowel

- PROCEDURE:

- The standard consistency of a cement paste is defined as that consistency which will permit the Vicat plunger G (dia. 10 ± 0.05 mm) shown above to penetrate to a point 5 to 7 mm from the bottom of the Vicat mould when the cement paste is tested as described below.

- Prepare a paste of weighed quantity of Cement(300gms) with a weighed quantity of potable or distilled water, taking care that the time of gauging is not less than 3 minutes, nor more than 5 min, and the gauging shall be completed before any sign of setting occurs.

- The gauging time shall be counted from the time of adding water to the dry cement until commencing to fill the mould.

- Fill the Vicat mould with this paste, the mould resting upon a non-porous plate (e.g., glass plate). After completely filling the mould, smoothen the surface of the paste, making it level with the top of the mould. The mould may be slightly shaken to expel the air.

- Clean appliances shall be used for gauging. In filling the mould, the operator’s hands and the blade of the gauging trowel shall alone be used.

- Place the test block in the mould, together with the non-porous resting plate, under the rod bearing the plunger; lower the plunger gently to touch the surface of the test block, and quickly release, allowing it to sink into the paste. This operation shall be carried out immediately after filling the mould.

- Prepare trial pastes with varying percentages of water and test as described above until the amount of water necessary for making up the standard consistency as defined in step 1 is found.

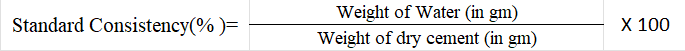

- CALCULATION:

Express the amount of water as a percentage by mass of the dry cement to the first place of decimal:

- PRECAUTION:

Care shall be taken to maintain the specified temperature, humidity, and the time of mixing so as to avoid setting of cement paste.

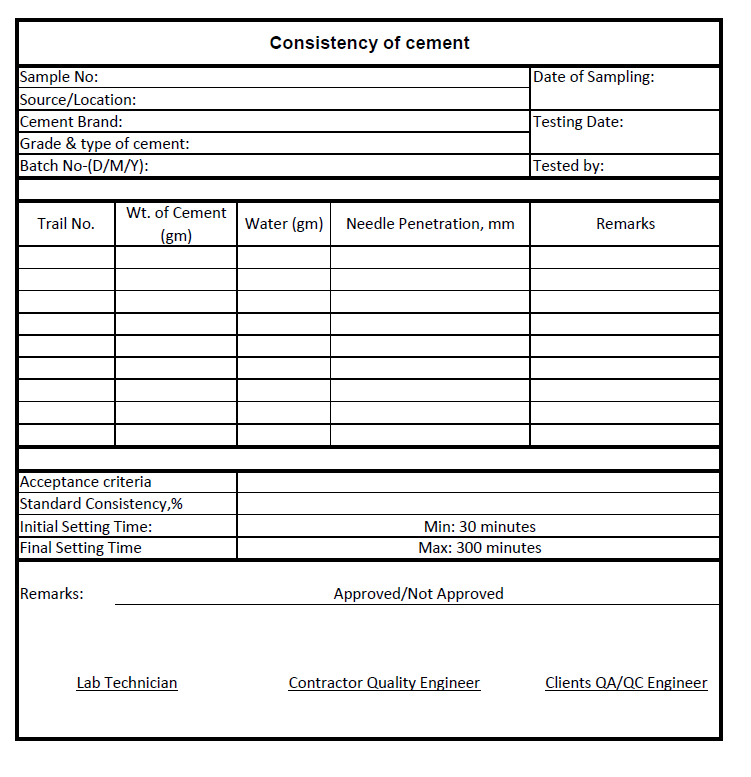

- FORMAT OF RECORD:

Use the below format to input the data and findings. Get it signed and keep it in file for future reference :