DETERMINATION OF INITIAL AND FINAL SETTING TIMES OF CEMENT

Codes : Is 4031-Part 5, ASTM C191

- Definition:

Initial Setting Time:

The period elapsing between the time when water is added to the cement and the time at which the needle (diameter 1.13 ± 0.05 mm) fails to pierce the test block to a point 5.0 ± 0.5 mm measured from the bottom of the mould shall be the Initial setting time.

Final Setting Time:

The period elapsing between the time when water is added to the cement and the time at which the needle(diameter 5 ± 0.1 mm) makes an impression on the surface of test block while the attachment fails to do so shall be the Final setting time.

- SCOPE/USE:

The Code IS 4031-Part 5 & ASTM C191 covers the procedure for determining of Initial and Final Setting time of Cement.

- SAMPLING:

The samples of the cement shall be taken in accordance with the requirements of IS: 3535- 1986 and the relevant standard specification for the type of cement being tested. The representative sample of the cement selected as above shall be thoroughly mixed before testing.

- TEMPERATURE AND HUMIDITY:

The temperature of moulding room, dry materials and water shall be maintained at 27 ± 2°C. The relative humidity of the laboratory shall be 65 ± 5 percent.

- MATERIALS REQUIRED: Cement and Water.

- APPARATUS: –

- Vicat apparatus

- Diameter of needle: 13 ± 0.05 mm

- Weight balance (Permissible variation at a load of 1000g shall be ±0g)

- Non-porous plate (One glass plate 300 x 450mm).

- Glass measuring cylinder, 200 or 250ml

- Gauging Trowel

- Standard Weights

Needles used for determination of Initial and Final Setting time of Cement:

|

|

| Needle C (Diameter 1.13±0.05 mm)

Used in Initial Setting time Test |

Needle F (Diameter 5 ± 0.1 mm)

Used in Final Setting time Test |

- Preparation of Test Block:

- Prepare a neat cement paste by gauging the cement with 0.85 times the water required to give a paste of standard consistency. Potable or distilled water shall be used in preparing the paste.

- Note the time at the instant when water is added to the cement(T₁). Fill the Vicat mould with a cement paste gauged as above, the mould resting on a nonporous plate. Fill the mould completely and smooth off the surface of the paste making it level with the top of the mould.

The cement block thus prepared in the mould is the test block.

- Determination of Initial Setting Time:

- Place the test block confined in the mould and resting on the non-porous plate, under the rod bearing the needle C (Diameter 1.13 ± 05 mm).

- Lower the needle gently until it comes in contact with the surface of the test block and quickly release, allowing it to penetrate into the test block.

- In the beginning, the needle will completely pierce the test block.

- Repeat this procedure until the needle, when brought in contact with the test block and released as described above, fails to pierce the block beyond 5.0 ± 0.5 mm measured from the bottom of the mould. Note the time (T₂).

- The period elapsing between the time when water is added to the cement and the time at which the needle fails to pierce the test block to a point 5.0 ± 0.5 mm measured from the bottom of the mould shall be the initial setting time.

- Calculation:

Initial Setting Time = T₂ – T₁

T₁ =Time at which water is first added to cement.

T₂ =Time when needle fails to penetrate 5.0 ± 0.5 mm measured from bottom of the mould.

- Determination of Final Setting Time:

- Replace the needle (C) of the Vicat apparatus by the needle with an annular attachment (F).

- The cement shall be considered as finally set when, upon applying the needle gently to the surface of the test block, the needle makes an impression thereon, while the attachment fails to do so. Note the time (T₃).

- The period elapsing between the time when water is added to the cement and the time at which the needle makes an impression on the surface of test block while the attachment fails to do so shall be the Final setting time.

- In the event of a scum forming on the surface of the test block, use the underside of the block for the determination.

- Calculation:

Final Setting Time = T₃ – T₁

T₁ =Time at which water is first added to cement

T₃ = Time when the needle makes an impression, but the attachment fails to do so.

- REPORTING OF RESULTS:

The results of initial and final setting time shall be reported to the nearest five minutes.

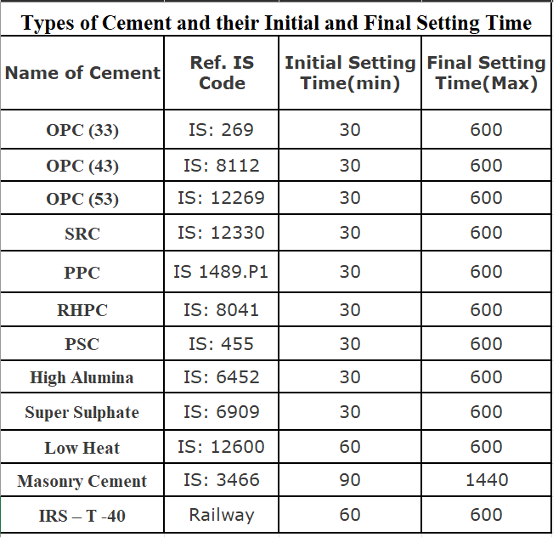

- Initial and Final setting time for various cement types used in construction is mentioned below. The Initial Setting time should be greater than 30 minutes and Final setting time should not exceed 300 minutes (10 hours) as per IS code 456:2000.

FAQ: Frequently asked Questions

Q.1. What is Initial Setting Time of cement?

Ans: The period elapsing between the time when water is added to the cement and the time at which the needle (diameter 1.13 ± 0.05 mm) fails to pierce the test block to a point 5.0 ± 0.5 mm measured from the bottom of the mould shall be the Initial setting time.

Q.2. What is Final Setting time of cement?

Ans:The period elapsing between the time when water is added to the cement and the time at which the needle(diameter 5 ± 0.1 mm) makes an impression on the surface of test block while the attachment fails to do so shall be the Final setting time.

Q.3. Which IS code is used to determine Initial and Final Setting time of cement?

Ans: Is 4031-Part 5

Q.4. What is the minimum time for Initial Setting time of cement?

Ans: The Initial Setting time should be greater than 30 minutes as per IS 456:2000.

Q.5. What is the maximum time for Final Setting time of cement?

Ans: The Final setting time should not exceed 300 minutes (10 hours) as per IS code 456:2000.